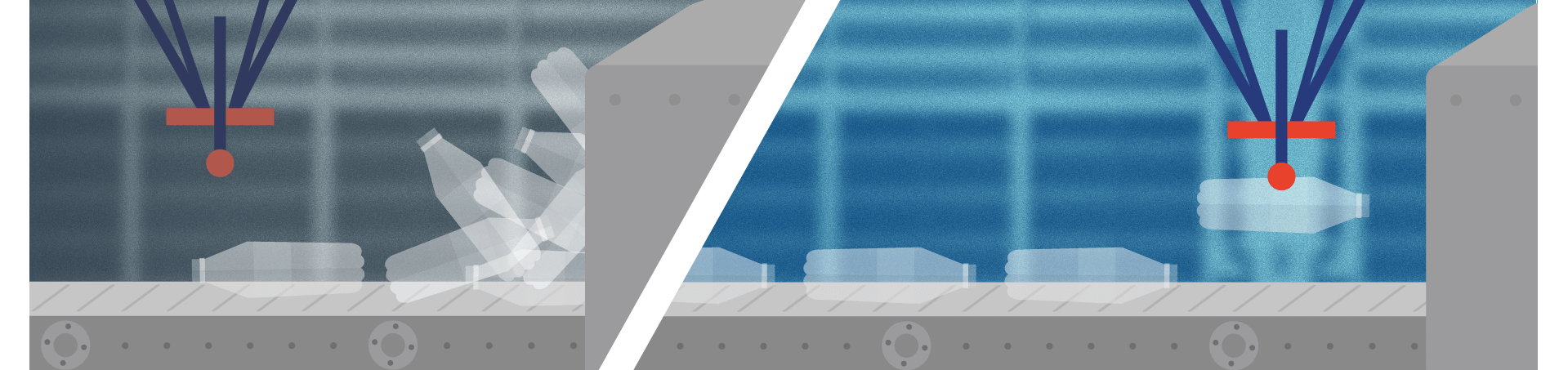

Bottles must rotate freely as they pass through the production conveyor, as forced rotation caused by friction can lead to a blockage on the line. The new SUKANO® Mobility Aid solution is provided as a solid PET masterbatch that is blended with virgin PET or RPET material during molding or processing. Even at low concentrations, the masterbatch disperses consistently through the PET material, reducing its coefficient of friction (COF), and modifying the surface texture with a microstructure.

Please enter your personal data to download the file from our download section.